Top Questions Packaging Companies Should Ask PET Preform Suppliers Before Signing a Contract

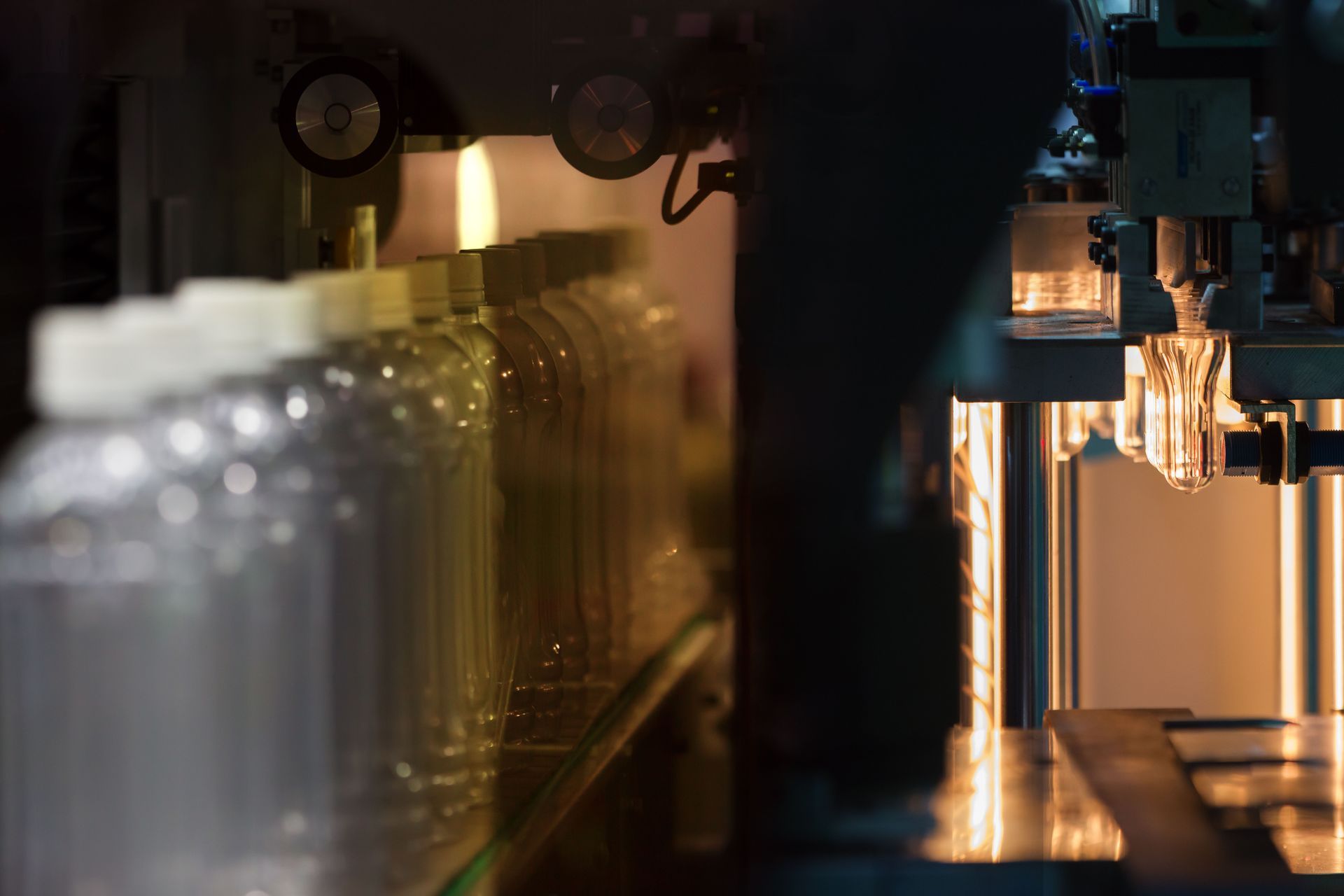

Packaging companies operate in an environment where consistency, efficiency, and material quality directly affect production timelines and brand reputation. When packaging performance falls short, it can lead to wasted materials, line slowdowns, or finished products that do not meet customer expectations. For companies that rely on PET bottles, the quality of preforms plays a foundational role in every stage of manufacturing, from molding to filling and distribution.

Selecting the right supplier is not a decision to rush. PET preforms influence bottle strength, clarity, weight, and recyclability, all of which can affect downstream operations and sustainability goals. With global attention on responsible packaging and performance standards, asking the right questions before signing a contract helps avoid costly issues later. According to the PET Resin Association, over 30% of PET bottles were recycled globally in recent years, although this figure varies by region. This growing emphasis on recycling and material efficiency makes supplier selection even more important. In this article, we'll cover the top questions packaging companies should ask PET preform suppliers before signing a contract.

What Quality Standards Do You Follow for PET Preforms?

One of the first questions packaging companies should ask is how a supplier defines and maintains quality. PET preforms must meet strict dimensional tolerances, weight specifications, and clarity standards to perform consistently during blow molding. A supplier's quality control processes provide insight into how reliably those standards are upheld.

Understanding whether a supplier follows recognized industry standards or internal quality benchmarks can reveal how much emphasis they place on consistency. Regular inspections, material testing, and documented procedures all contribute to reliable output. Clear answers to this question help packaging companies assess whether a supplier's quality approach aligns with their own production requirements.

How Do You Source and Manage Raw PET Materials?

The quality of PET preforms begins with the resin used to produce them. Packaging companies should ask suppliers where their raw materials come from and how those materials are monitored throughout production. Resin quality can affect bottle strength, transparency, and long-term performance.

Suppliers that maintain strong sourcing practices and consistent material specifications are better positioned to deliver predictable results. This question also opens the door to discussions about recycled content and material traceability. As sustainability continues to shape packaging decisions, transparency around raw material sourcing has become increasingly important.

Can You Support Consistent Volume and Long-Term Demand?

Production planning depends heavily on a reliable supply. Packaging companies should ask whether a supplier can handle current volume needs while also scaling for future growth. Inconsistent delivery schedules or production limits can disrupt operations and create costly delays.

A strong supplier will be able to discuss capacity, lead times, and contingency planning with confidence. This includes how they manage demand fluctuations and unexpected changes in order size. Asking this question helps determine whether PET preform suppliers can support both short-term needs and long-term partnerships.

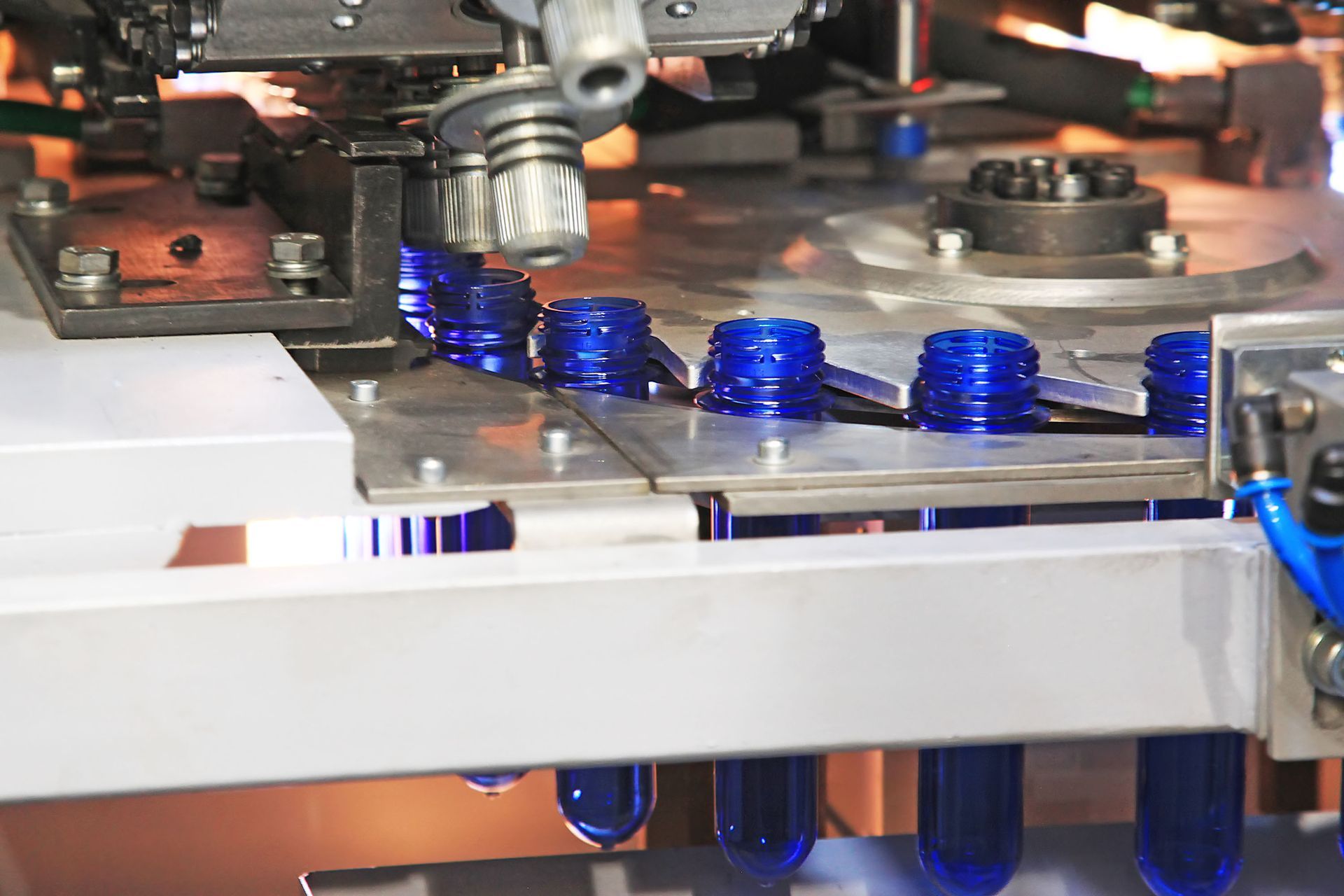

What Customization Options Are Available for Preforms?

Not all PET bottles are created equal. Different products require specific neck finishes, weights, and design characteristics. Packaging companies should ask what level of customization a supplier offers and how flexible they are with design adjustments.

Suppliers with experience supporting diverse packaging applications often provide guidance on optimizing preform design for performance and efficiency. This question also reveals how collaborative the supplier is during development and whether they can adapt to evolving packaging requirements over time.

How Do You Maintain Consistency Across Production Batches?

Even minor variations in preform dimensions can affect blow molding performance and finished bottle quality. Packaging companies should ask how suppliers control batch-to-batch consistency and what systems are in place to prevent variation.

This includes monitoring tooling, maintaining equipment, and conducting routine checks throughout production. Reliable PET preform suppliers understand that consistency is just as important as initial quality, especially for high-speed production lines where small deviations can have large impacts.

What Sustainability Practices Are Integrated Into Your Operations?

Sustainability has become a core consideration for packaging companies across industries. Asking suppliers about their environmental practices helps align sourcing decisions with broader corporate goals. This includes energy usage, waste reduction, and support for recycled PET initiatives.

According to the PET Resin Association, over 30% of PET bottles were recycled globally in recent years, although this figure varies by region. Suppliers that actively support recycling efforts and material efficiency can help packaging companies strengthen sustainability messaging while improving operational outcomes.

How Do You Handle Quality Issues or Production Challenges?

No manufacturing process is immune to challenges, which makes response strategies critical. Packaging companies should ask how suppliers address quality issues if they arise and what corrective measures are in place.

Clear procedures for identifying root causes, communicating issues, and implementing solutions indicate a proactive approach. Suppliers that are transparent about how they manage challenges are often better partners during unexpected situations. This question helps set expectations for accountability and responsiveness.

What Lead Times and Logistics Support Do You Offer?

Reliable logistics are just as important as production quality. Packaging companies should understand how long it takes to receive orders and what shipping options are available. Lead times can affect inventory planning and production scheduling.

Suppliers that offer flexible delivery options, clear timelines, and consistent communication help reduce uncertainty. Asking about logistics support also highlights how well PET preform suppliers integrate into broader supply chains, which is essential for maintaining smooth operations.

Do You Provide Technical Support and Documentation?

Technical support can be a valuable resource during both onboarding and ongoing production. Packaging companies should ask whether suppliers provide documentation, specifications, and troubleshooting assistance when needed.

Access to knowledgeable technical support helps resolve issues faster and supports efficient line operation. This question also reveals whether the supplier takes an active role in supporting customer success beyond simply delivering products.

How Do Pricing Structures and Contracts Work?

Understanding pricing is essential before committing to a long-term agreement. Packaging companies should ask how pricing is structured, what factors influence costs, and how changes in volume or materials might affect pricing over time.

Clear contract terms help avoid misunderstandings and support budget planning. Transparent pricing discussions also indicate how upfront and communicative PET preform suppliers are about the financial side of the partnership.

What Experience Do You Have With Similar Packaging Applications?

Experience matters, especially when suppliers serve specific industries or product types. Packaging companies should ask about a supplier's track record with similar applications to their own.

Suppliers familiar with comparable production environments often anticipate challenges more effectively and offer practical insights. This question helps packaging companies evaluate whether a supplier understands their operational context and performance expectations.

How Do You Support Long-Term Partnerships?

Finally, packaging companies should ask how suppliers approach long-term relationships. This includes communication practices, account management, and ongoing improvement efforts.

Suppliers that value collaboration and continuous improvement tend to adapt more readily as needs evolve. Asking this question helps determine whether PET preform suppliers see the relationship as transactional or as a long-term partnership focused on shared success.

If your packaging company is preparing to evaluate or renew a supplier agreement, now is the ideal time to start asking these critical questions. Partner with a PET preform supplier that aligns with your production needs, sustainability priorities, and growth plans, and take the next step toward a more reliable and efficient packaging operation. Reach out to our team at Preform Solutions, Inc today!

Share On: