Why Pet Preform Is One of the Leading Solutions in 2025

The packaging industry has seen remarkable advancements over the past decade, driven by sustainability, efficiency, and safety concerns. Among these innovations, the PET preform for water bottles has emerged as a leading solution for manufacturers and consumers alike. With its versatile design, environmental benefits, and compatibility with modern production processes, PET preforms are reshaping the way beverages are packaged and distributed worldwide. As 2025 progresses, understanding the reasons behind the rise of PET preforms is essential for businesses aiming to stay ahead in the competitive market.

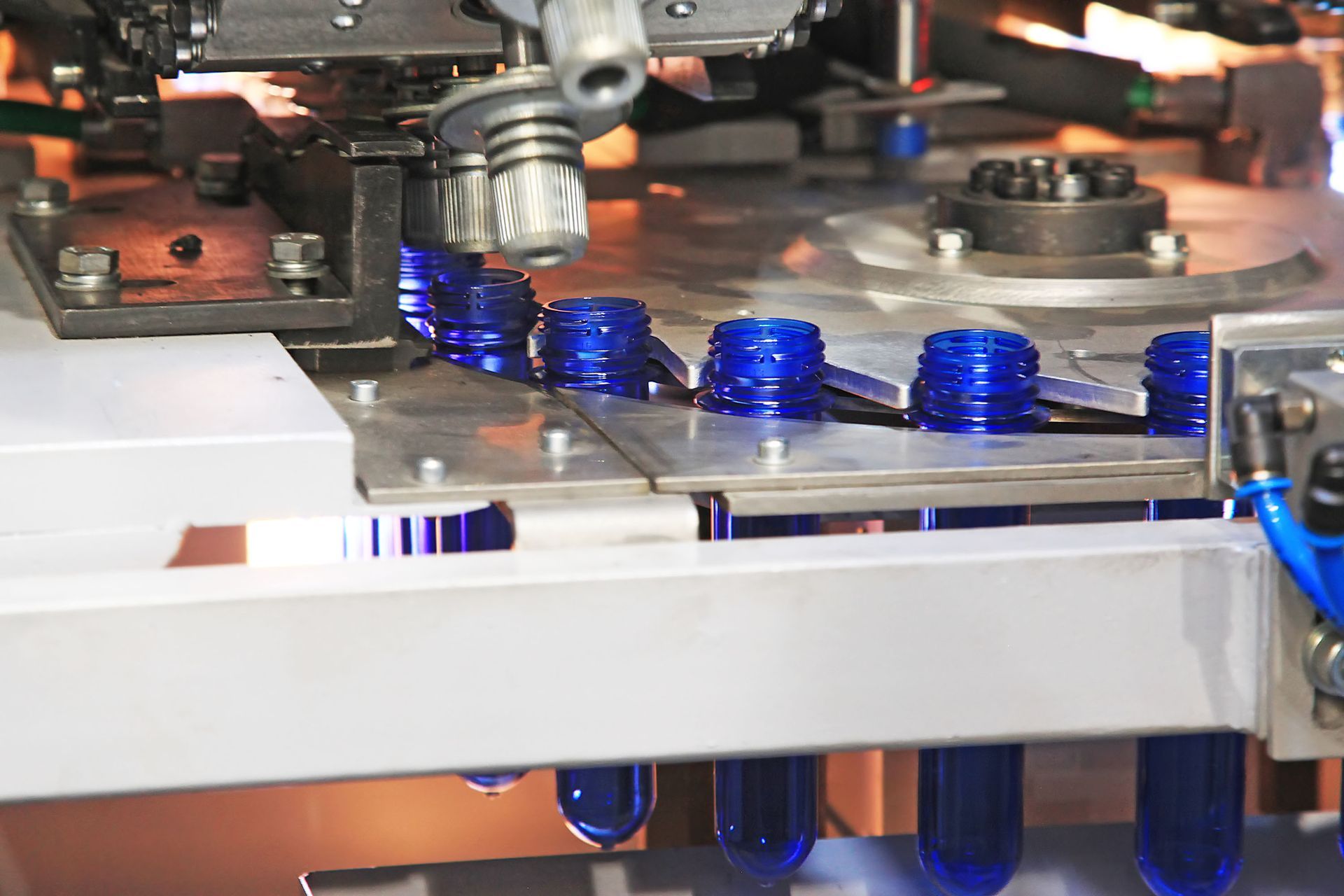

The Rise of Pet Preform Technology

A PET preform is the small, tube-like piece of plastic that is later blown into a fully formed water bottle. This process, known as stretch blow molding, allows manufacturers to produce bottles of varying sizes and shapes efficiently. The versatility of PET preforms has made them a staple in beverage packaging, especially for water, soft drinks, and other liquid consumables.

One of the primary factors behind the popularity of PET preforms is the ability to control production costs without compromising quality. By producing preforms in bulk and storing them until needed, manufacturers can respond quickly to market demands while reducing waste. This modular approach also simplifies shipping logistics, as preforms take up less space than fully formed bottles, ultimately lowering transportation costs.

In addition, PET preforms offer manufacturers a high level of consistency. Each preform is molded under strict specifications, ensuring that the final water bottle maintains uniform thickness, clarity, and structural integrity. This consistency is critical for brands seeking to maintain a high-quality consumer experience while meeting regulatory standards.

Sustainability Advantages of Pet Preforms

Environmental concerns are driving significant changes in the packaging industry, and PET preforms offer several advantages in this area. First, they are highly recyclable. The PET plastic used in preforms can be collected, cleaned, and reprocessed into new bottles, fibers, or other materials. This reduces the need for virgin plastic and minimizes the environmental impact associated with beverage packaging.

Moreover, the lightweight nature of PET preforms contributes to lower carbon emissions during transportation. Since preforms are smaller and lighter than finished bottles, shipping them consumes less fuel, translating to a smaller carbon footprint. In an era where consumers increasingly prioritize eco-friendly practices, this aspect of PET preforms aligns well with sustainable branding initiatives.

Manufacturers are also exploring the use of recycled PET (rPET) in producing new preforms. By incorporating recycled material without compromising quality or safety, companies can create products that meet environmental goals while remaining economically viable. This shift toward circular production models reinforces the role of PET preforms for water bottles in sustainable packaging solutions.

Safety and Compliance With Regulatory Standards

Safety is a paramount concern when it comes to packaging food and beverages. According to the U.S. Food and Drug Administration (FDA), PET plastic is approved for use in food and beverage packaging, which means that products made from PET, including PET preforms, meet strict safety standards. This certification ensures that water bottles produced from PET preforms are safe for consumer use, free from harmful chemicals, and suitable for long-term storage of liquids.

The FDA approval is particularly important for companies looking to export products to international markets. Compliance with safety regulations not only protects consumers but also builds trust in a brand's commitment to quality. By using a PET preform for water bottles, manufacturers can reassure customers that their packaging meets the highest safety standards while maintaining the durability and convenience expected from modern water bottles.

Beyond regulatory compliance, PET preforms also offer practical benefits that enhance product safety. Their uniform construction minimizes the risk of leaks or contamination, and the material's resistance to impact and temperature variations helps preserve the quality of the beverage throughout its shelf life. By combining FDA-approved safety with reliable physical performance, PET preforms provide both manufacturers and consumers with peace of mind in every bottle.

Cost Efficiency in Production and Distribution

One of the most compelling reasons for the widespread adoption of PET preforms is cost efficiency. The production process for preforms is faster and less resource-intensive compared to traditional bottle manufacturing methods. High-volume injection molding allows manufacturers to create thousands of preforms in a single run, optimizing production schedules and minimizing downtime. This streamlined process also reduces energy consumption, contributing to both economic and environmental benefits.

The modular nature of preforms also supports flexibility in distribution. Bottlers can store preforms at centralized facilities and produce water bottles as needed, responding rapidly to fluctuations in demand. This approach reduces inventory costs and minimizes the risk of overproduction, a significant concern in the competitive beverage market. Such adaptability allows companies to better align production with consumer demand and market trends.

Additionally, the lightweight design of preforms lowers shipping costs for manufacturers and distributors. Transporting preforms instead of fully formed bottles reduces packaging volume and weight, resulting in substantial cost savings over time. These financial benefits make PET preform for water bottle solutions an attractive option for businesses seeking both efficiency and scalability. Over time, these savings can be reinvested into innovation, quality improvement, or sustainable initiatives.

Innovation and Design Flexibility

Another key factor driving the adoption of PET preforms is the innovation and design flexibility they offer. Preforms can be customized to meet specific brand requirements, from bottle size and shape to cap threading and wall thickness. This flexibility allows companies to create unique packaging that stands out on store shelves while maintaining structural integrity and consumer safety.

Advances in technology have also enabled manufacturers to produce preforms with specialized features, such as enhanced clarity, UV resistance, or ergonomic designs. These improvements cater to consumer preferences and lifestyle trends, making a PET preform for water bottles a versatile tool for brand differentiation.

Furthermore, the ability to scale production without sacrificing quality encourages continuous innovation. Companies can experiment with new bottle shapes, materials, and designs while leveraging the efficiency of preform manufacturing. This combination of creativity and practicality positions PET preforms as a forward-looking solution in the packaging industry, well-suited to meet the demands of 2025 and beyond.

As the beverage industry continues to evolve, the importance of reliable, sustainable, and safe packaging solutions cannot be overstated. The PET preform for water bottles has emerged as a leading technology, offering unmatched versatility, cost efficiency, and environmental benefits. From FDA-approved safety standards to scalable production processes, PET preforms address both the practical and strategic needs of manufacturers, distributors, and consumers.

Looking ahead, the role of PET preforms is expected to grow as companies invest in sustainable practices, innovative designs, and global distribution capabilities. Their lightweight, recyclable nature aligns with the increasing consumer demand for eco-friendly packaging, while the flexibility of production supports cost-effective operations. In essence, PET preforms are more than just a manufacturing convenience — they are a key driver of progress in the packaging sector.

For businesses aiming to stay competitive in 2025, embracing PET preform for water bottle solutions offers a clear path forward. By combining efficiency, safety, and sustainability, PET preforms provide a practical yet innovative approach to beverage packaging, meeting the expectations of both consumers and regulatory authorities alike. As trends shift toward more environmentally conscious and design-focused packaging, the continued adoption of PET preforms will undoubtedly define the future of the industry. If you're looking for a PET preform molding company, contact Preform Solutions, Inc today!

Share On: